29 November 2018

The new PM12 paper machine for the production of tissue paper is now up and running in Porcari

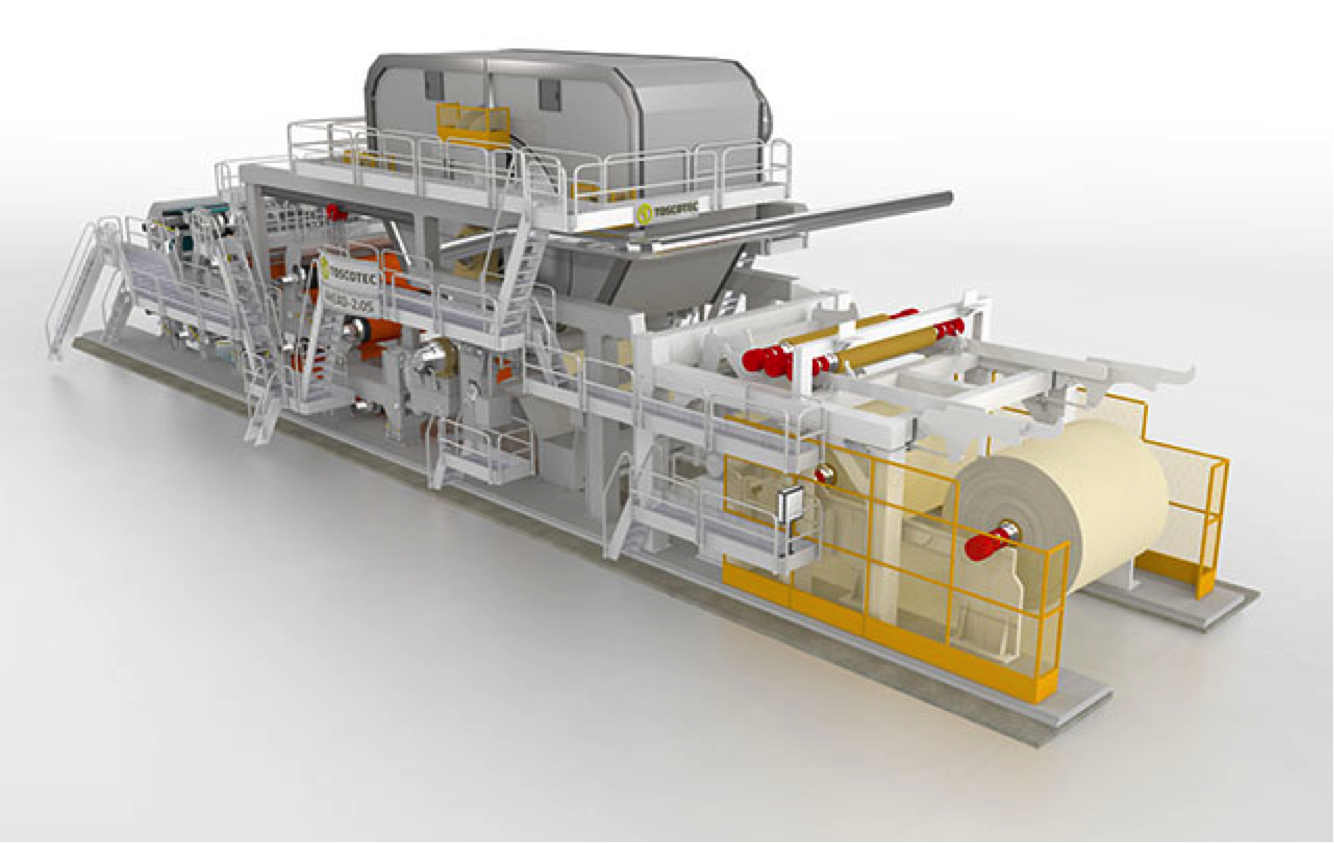

The new tissue paper production line was successfully started up at the Lucart plant in Porcari near Lucca. The PM12 line replaced the number 2 machine which, since 1976, has been producing MG paper for the flexible packaging market worldwide. The paper machine was made by Toscotec, leading manufacturer of systems, machinery and technology for paper making with headquarters near Lucca.

The technical features of the new PM12 paper machine

The new tissue machine is an AHEAD-2.0S, with TT NextPress system, next-generation steel MG TT SYD-16FT and high-efficiency hoods to guarantee the production of high-quality paper with minimum energy consumption.

To guarantee a working environment that complies with the latest regulations in force, the paper machine is equipped with a system of suction of the mist and dust generated during the production process. Also installed a new model of automatic rewinder with technology aimed at maintaining the thickness of the paper during the winding phase of the reel

The line can made high-quality tissue paper at a working speed of 2000 mpm. It has a total production capacity of about 35,000 tonnes per year. The MG papers, which until June were produced on line 2, have been moved to line 3 to maintain the range and quality of papers for the flexible packaging sector.

"The start-up of the new Porcari line makes us very happy because it allows us to strengthen our presence in the tissue paper market", explained Massimo Pasquini, CEO of Lucart. "We consider the company's growth in the European sanitary paper markets to be strategic and the new paper machine will help the development of all the Business Units of our Group. We are also happy to take a step towards innovation without forgetting our origins, but rather enhancing them. Not by chance, we have chosen to install such cutting-edge technology in our time-honoured plant in Porcari precisely to give a positive message at a national level at such a complex time for business and entrepreneurship. Working with a partner like Toscotec was one of the plus points of this project, a valuable experience that we hope will continue in the future".

"The project was a challenging one and Lucart together with Toscotec has involved other Italian companies, in particular, EIL, Euromont, Still, CMSA that have always proved to be up to the needs with competence and professionalism", declared Franco Pasquini, Chief Technology Officer at Lucart.

"We are proud to be part of the growth project of Lucart", commented Alessandro Mennucci, CEO of Toscotec. "Toscotec exports worldwide, but we are proud to be able to put our state-of-the-art technology at the service of a recognised and important Group such as Lucart Group. We are confident that the new plant in Porcari will meet the expectations in terms of both finished product quality and efficiency and consumption. We will continue to follow this important partner closely, hoping to continue this cooperation in the long term"

The technical features of the new PM12 paper machine

The new tissue machine is an AHEAD-2.0S, with TT NextPress system, next-generation steel MG TT SYD-16FT and high-efficiency hoods to guarantee the production of high-quality paper with minimum energy consumption.

To guarantee a working environment that complies with the latest regulations in force, the paper machine is equipped with a system of suction of the mist and dust generated during the production process. Also installed a new model of automatic rewinder with technology aimed at maintaining the thickness of the paper during the winding phase of the reel

The line can made high-quality tissue paper at a working speed of 2000 mpm. It has a total production capacity of about 35,000 tonnes per year. The MG papers, which until June were produced on line 2, have been moved to line 3 to maintain the range and quality of papers for the flexible packaging sector.

"The start-up of the new Porcari line makes us very happy because it allows us to strengthen our presence in the tissue paper market", explained Massimo Pasquini, CEO of Lucart. "We consider the company's growth in the European sanitary paper markets to be strategic and the new paper machine will help the development of all the Business Units of our Group. We are also happy to take a step towards innovation without forgetting our origins, but rather enhancing them. Not by chance, we have chosen to install such cutting-edge technology in our time-honoured plant in Porcari precisely to give a positive message at a national level at such a complex time for business and entrepreneurship. Working with a partner like Toscotec was one of the plus points of this project, a valuable experience that we hope will continue in the future".

"The project was a challenging one and Lucart together with Toscotec has involved other Italian companies, in particular, EIL, Euromont, Still, CMSA that have always proved to be up to the needs with competence and professionalism", declared Franco Pasquini, Chief Technology Officer at Lucart.

"We are proud to be part of the growth project of Lucart", commented Alessandro Mennucci, CEO of Toscotec. "Toscotec exports worldwide, but we are proud to be able to put our state-of-the-art technology at the service of a recognised and important Group such as Lucart Group. We are confident that the new plant in Porcari will meet the expectations in terms of both finished product quality and efficiency and consumption. We will continue to follow this important partner closely, hoping to continue this cooperation in the long term"

Investments, BusinessToBusiness, Corporate